Click on any picture to enlarge. Click on the picture again to minimise.

This page shows the fabrication and installation of a lead roof vent which will, once a plumber has been to site, vent two bathrooms.

The vent was installed on a high castle roof but no scaffold costs were incurred as we do not need scaffold for this kind of work.

Access, leadwork and slating were all handled by BCM Steeplejacks – no subcontractors were required, which helps to keep costs down.

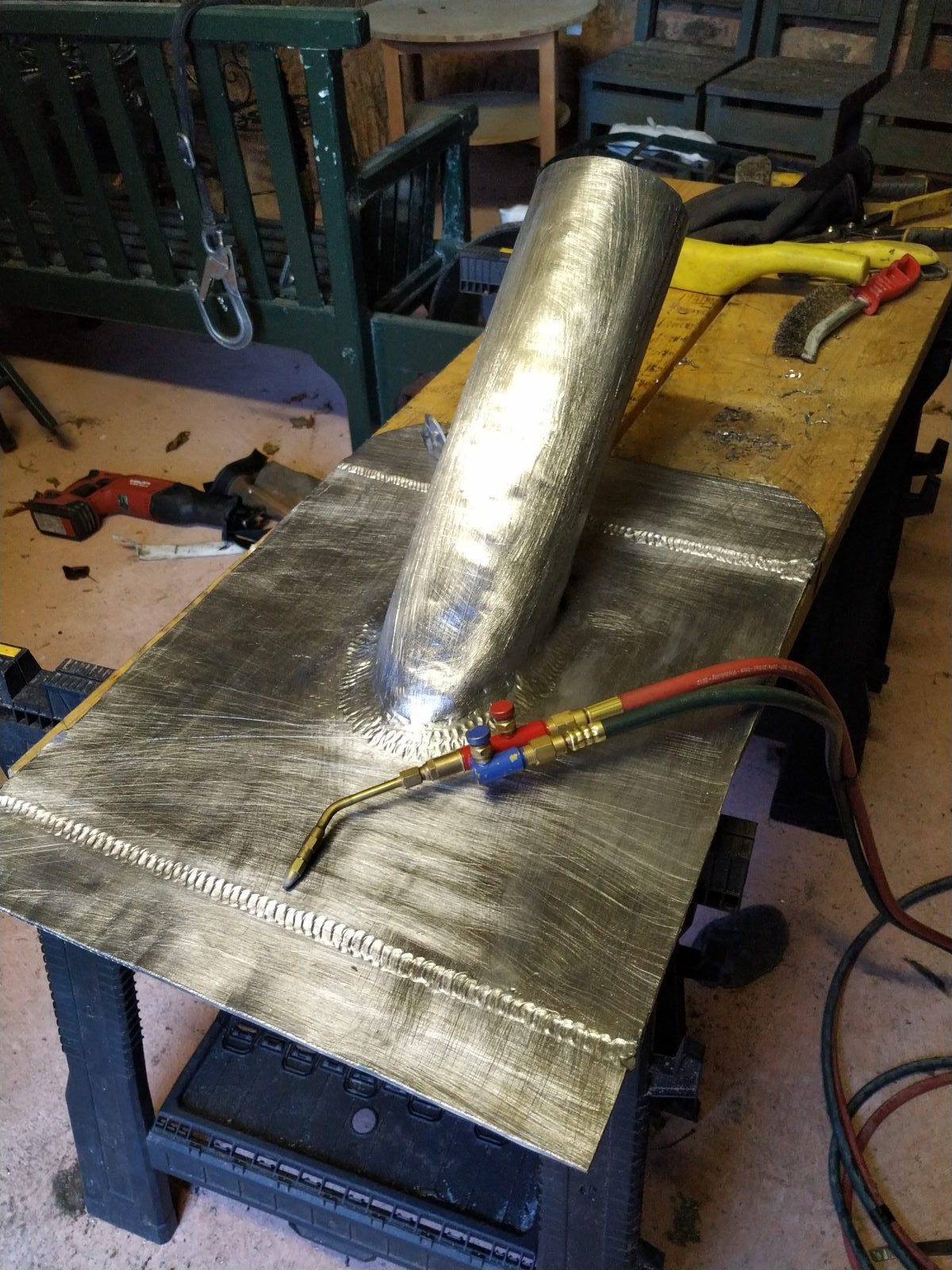

This picture shows the vent on the bench during fabrication. The plastic pipe inside the outer lead pipe is there to give the plumber something to connect onto inside the attic.

Still on the bench but nearly complete.

We added a lead cowl to keep the rain out. The vent is now complete and ready to be installed into the roof.

Vent in position.

Slating around the vent.

These two pictures show the completed job.

Finally, here is the internal plastic pipe.